- Products

- Segments

- Newsroom

- Tools and Resources

- Sustainability

- We are Nexans

- Search

- Contact us

- Compare

- Sign in

From idea to smart reality

-

LOCATIONNorway

-

PARTNERSHIPUtility

-

SolutionSmart cables

Troms Kraft may have saved up to 90% of the cost of establishing fiber. Not only that, Nexans’ smart cable paves the wave for complying with the likely regulatory requirements of the future.

According to Ansgar Wilhelmsen, Power Grid Engineer, Multipurpose Cabling, Troms Kraft (TK). And Wilhelmsen has years of experience and professional standing behind his assertions. He has worked for TK for almost 45 years,the last 20 of which were in communication.

“Here in the city, we had plans to lay fiber cables back in 1998, and I was in charge of future communication. But in many places, fiber cables was never laid due to the cost. The excavation costs in Tromsø were too high,” Wilhelmsen says.

Just a trench

This was the reality confronting Wilhelmsen and his TK colleagues. But Wilhelmsen not someone who lets ‘reality’ get in his way.

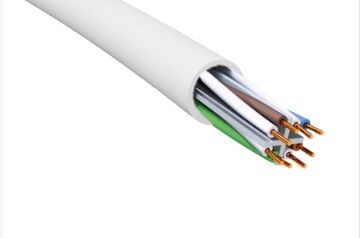

“I was convinced that properly laying a fiber cable or a conduit for fiber along with a power cable was a no-brainer. Doing this would save us the cost of laying fiber later on,” he says.

User meets manufacturer

When ‘Gyro Gearloose’ gets a good idea, he goes to his workshop with his sidekick. Wilhelmsen didn’t have this option. On the other hand, he reached out to eight different cable manufacturers to discuss what he thought was a clever idea.

“Few people were receptive to my idea, except for an enthusiastic Trond Nesbakken at Nexans. He and I have the same background as electricians, and we speak the same language. Without the personal and professional relationship between us, the O-cable would never have seen the light of day,” he says.

Successful startup

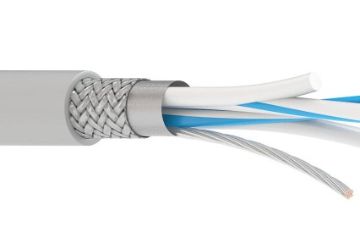

This began a process of trial and error and brainstorming meetings between Troms Kraft and the manufacturer. The solution – Nexans’ O-cable or smart cable – came about as a result of wanting to meet TK’s needs, Wilhelmsen’s creativity, Nesbakken’s innovation and Nexans’ technological expertise.

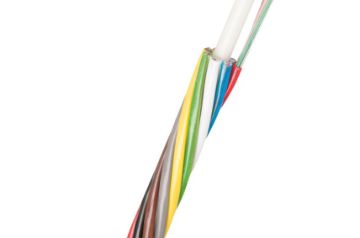

In 2007, the first cabling system – comprising Nexans’ braided 24 kV power cable including three empty conduits and a 1 kV cable with an attached conduit – was laid in Målselv, a mountain village in Indre Troms. It was an immediate success.

“We blew fiber into the conduits of both cable types,” Wilhelmsen says.

Big savings for TK

Since then, the story has repeated itself, year after year. For Nexans, the smart cable significantly improved TK’s bottom line compared to what it would have been without Wilhelmsen’s good idea.

“We’ve saved tens of millions of kroner by using this invention, at any rate,” he says.

In addition to the obvious savings during cable-laying – laying one cable with multiple functions in one trench – the unused conduits have a sales potential all their own.

“TK must always keep at least one conduit empty for its own use. The other two can be sold or leased to interested parties. This is a big source of potential income,” he says.

Societal benefits

Nevertheless, the financial aspects were not Wilhelmsen’s main concern.

“Profitability is a beneficial side effect. Security, safety and quality were the driving forces. Not to mention the societal benefits,” he says.

Wilhelmsen underscores the vast consequences arising from a breakdown of communication lines.

“Contractors have greater respect for a power cable than a single fiber-filled cable. The fiber is much better protected in a conduit that is interwoven with the power cable,” he says.

Meets future requirements

Because TK has laid many meters of O-cable since 2007, they have secured a solution for themselves whenever the authorities – as Wilhelmsen predicts – tighten the safety requirements for Norway’s power stations.

“Whenever I gaze into my crystal ball, I see regulatory requirements for documentation and for secure communication between power stations, substations and transformer stations. In these instances, only fiber will do, and laying O-cable with or without pre-blown fiber means that the solution is already there,” he says, adding:

“I am skeptical about the fact that the national emergency grid depends on overhead cables. If it had been laid in conduits underground, we would have experienced less downtime,” thinks the clever originator of the smart cable idea.

Our websites

Select your country to find our products and solutions

-

Africa

- Africa

- Ghana

- Ivory Coast

- Morocco

- North West Africa

- Americas

- Asia

- Europe

- Oceania