- Products

- Segments

- Newsroom

- Tools and Resources

- Sustainability

- We are Nexans

- Search

- Contact us

- Compare

- Sign in

Power distribution

Nexans supplies submarine cables for the largest ever aquaculture electrification project

Sep 21, 2023

A pioneering product, strong expertise and good collaboration have taken NTE an important step towards becoming a key service provider in energy efficiency and optimisation.

– Our goal is to help accelerate the electrification and digitalisation of aquaculture with cost-effective and future-oriented solutions. We help our customers to significantly reduce the use of fossil fuels," says Rune Skaufel, Project Manager at NTE Marked.

Nord-Trøndelag Elektrisitetsverk (NTE) is a major power supplier, with 24 hydropower plants in Trøndelag and Nordland.

In 2021, they also started investing in aquaculture, and have become one of the leading centres of expertise in Norway for the electrification of fleets and boats in the aquaculture industry.

Responsible for historic electrification project

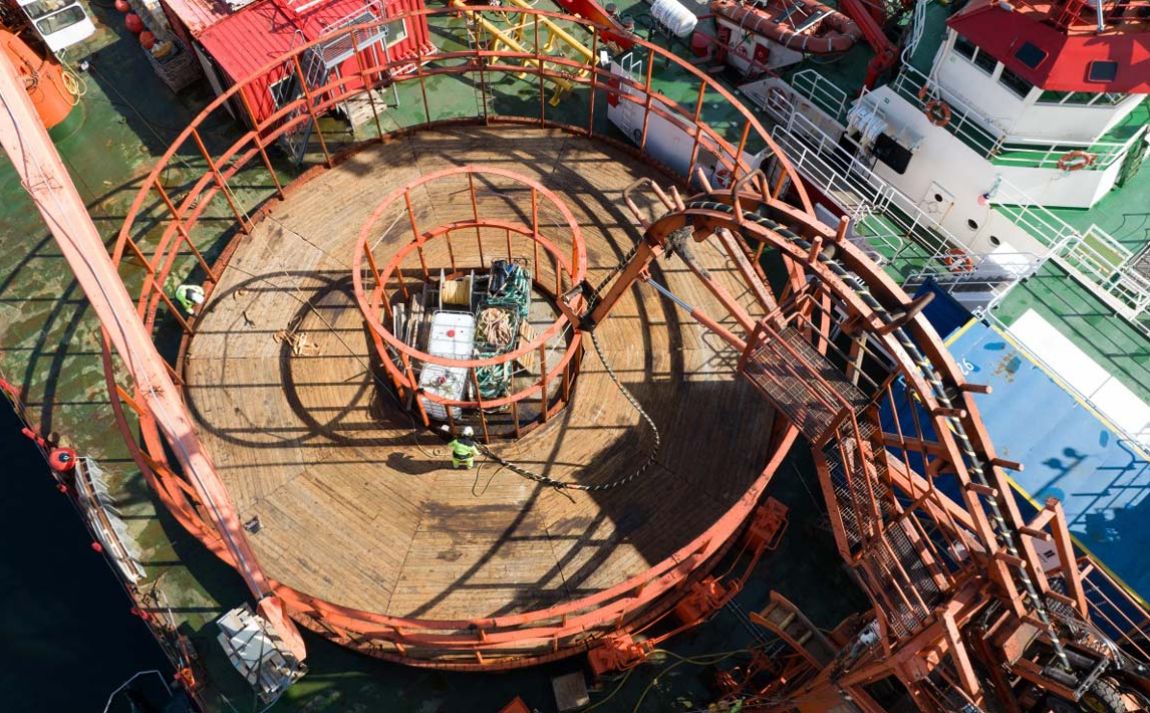

NTE recently reached an important milestone towards its goal. Three salmon farming sites outside Frøya were to electrify their feed barges with shore power and batteries. This is part of a larger project where a total of six feed barges will be electrified.

Using electricity and fibre from shore, the diesel generators were to be replaced, thereby saving the environment more than 600,000 litres of diesel annually. Such an electrification project has never been carried out in Norway before.

“ This is probably the largest aquaculture electrification project ever. ”

Rune Skaufel

And NTE was chosen as the turnkey contractor for this important project

But the electrification project will not only significantly reduce diesel consumption at the fish farms. It will also promote sustainable practices and environmental awareness in the industry.

This required cutting-edge and robust submarine cables.

WATCH VIDEO: See more about the electrification project in the video below

More than just a cable

Developing a cable suitable for such an important project is not a simple task. To handle the challenging conditions at sea, such as tides, waves and wind, innovative solutions were needed.

It has also been a special project for Nexans.

– For us, the project has been groundbreaking. It's the first time we've performed such a complex seamless phase splice on a delivered cross-section in a factory, both because of the dimensions and the fact that each strand has to be welded together," says Aleksander Hoel at cable manufacturer Nexans.

Another impressive achievement is that the newly delivered cable is 15 kilometres long and has only one splice. It is also double armoured and has extra protection in places where the cable can move in relation to the seabed.

In total, Nexans will deliver 29 kilometres of cable for this project. This is the longest stretch ever delivered in this dimension from the Rognan factory.

SEE MORE: See a selection of our submarine cables here.

No doubt about the choice of cable manufacturer

For NTE Elektro in Trondheim, the choice of cable supplier was clear right from the start. It had to be Nexans.

“ They were the first company we thought of. Nexans has a strong position and is almost a seal of quality in itself. ”

Georg Grongstad

Rune Skaufel is also very satisfied with both the collaboration and the product that was delivered. He says that he is proud to have developed the technical solution in collaboration with Nexans.

– With Nexans as a technical supporter, we got help to design and modify solutions. These are skilled people who really know their job, he says.

– A cable may seem simple, but it's actually very complex. Nexans is a technology company that delivers more than just a product. They are so good at Nexans in Rognan. That's where the expertise in submarine cables is located and they help find solutions.

Bonus with Norwegian and locally produced cable

They are both also concerned about the sustainable aspect of choosing a cable supplier. And the fact that the cable is manufactured in Norway, at Nexans Rognan near Bodø municipality, is an added bonus.

– It also provides reassurance that their products are Norwegian-made in terms of delivery reliability. Like us, they are committed to sustainability and they represent the right values for us," says Georg Grongstad.

“ Their products are of a very high technical standard, have a long lifespan and, best of all, are made in Norway ”

Rune Skaufel

Our websites

Select your country to find our products and solutions

-

Africa

- Africa

- Ghana

- Ivory Coast

- Morocco

- North West Africa

- Americas

- Asia

- Europe

- Oceania