- Products

- Segments

- Newsroom

- Tools and Resources

- Sustainability

- We are Nexans

- Search

- Contact us

- Compare

- Sign in

Constantly moving forwards

Martin Nilsson and Eric Nordetun are a part of the Production Engineering team at Nexans in Grimsås. This is a glimpse of a working day for them.

Nexans´ production units are in full swing. The occupancy rate is so high that it can sometimes be difficult to keep up with all the jobs. Therefore, the well-used Line 23 is being rebuilt to relieve other production lines.

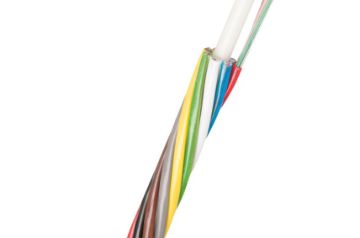

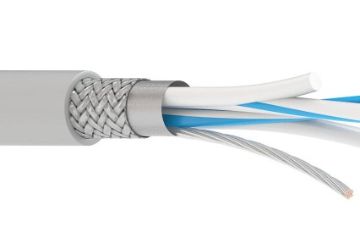

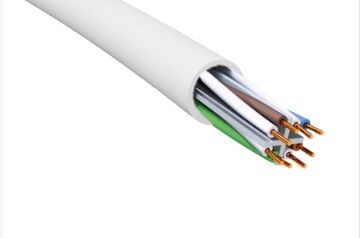

The line will, among other things, have three separate extruders that allow the cables that leave the machine to have sheaths in different materials. In the first stage, it is about halogen-free jackets, but three extruders open for jackets in polyethylene or PVC. Safety is also being upgraded, so that Line 23 can be CE marked.

It is a job for the Production Engineering team, with two project managers and seven process technicians. The project managers start the work when an order is placed. They budget, procure, demand money from headquarters and draw up time plans. A job where you sometimes have to stop yourself, according to project manager Martin Nilsson.

- Once the work has started, our perhaps most difficult task is to stick to the plan. It is easy to slip away and "broaden the project" when you are still working on it.

Once the machine is in place, process technicians take over. They are responsible for the steps from test drive to full production.

- We often start together with a representative from the supplier and the operator who will handle the machine. At the same time we order and test the tools required, mainly tips and dies that will form jacket material, says project technician Eric Nordetun.

When the machine is running properly, the cables it produces will be inspected.

- We leave the cables to our laboratory, which, among other things, checks mechanical properties and fire safety, says Eric Nordetun.

Finally, before the machine is released in production, Eric Nordetun documents everything that has been done in case something goes wrong or if someone else is to take over the assignment in the future.

How will customers notice the work with Line 23?

- Above all, they can look forward to increased delivery precision when we double the capacity of a requested cable. But other cables can also be delivered faster. And the cables get a more robust marking, says Martin Nilsson.

Our websites

Select your country to find our products and solutions

-

Africa

- Africa

- Ghana

- Ivory Coast

- Morocco

- North West Africa

- Americas

- Asia

- Europe

- Oceania